Parking Brake Solutions for the 14-Bolt Full Floating Axle

Parking Brake Solutions for the 14-Bolt Full Floating Axle

It is well known that the 14-bolt full floating GM axle (1973-1987) is a strong, cheap, and robust solution for off road / 4x4 use. The earlier axles had large drum brakes that included an integrated parking/emergency brake. While the drum brakes work okay if they are regularly serviced and kept clean, disk brakes are much lighter and in general outperform drum brakes in terms of maintenance, braking performance, and resistance to debris (e.g., water crossings). There are good disc brake conversions available using the front calipers from a ¾ ton Chevy truck (e.g. RuffStuff). The conversion kit, however, does not address the parking brake. For trucks equipped with an automatic transmission, lack of a park brake is not the end of the world but for a manual transmission it is essential.

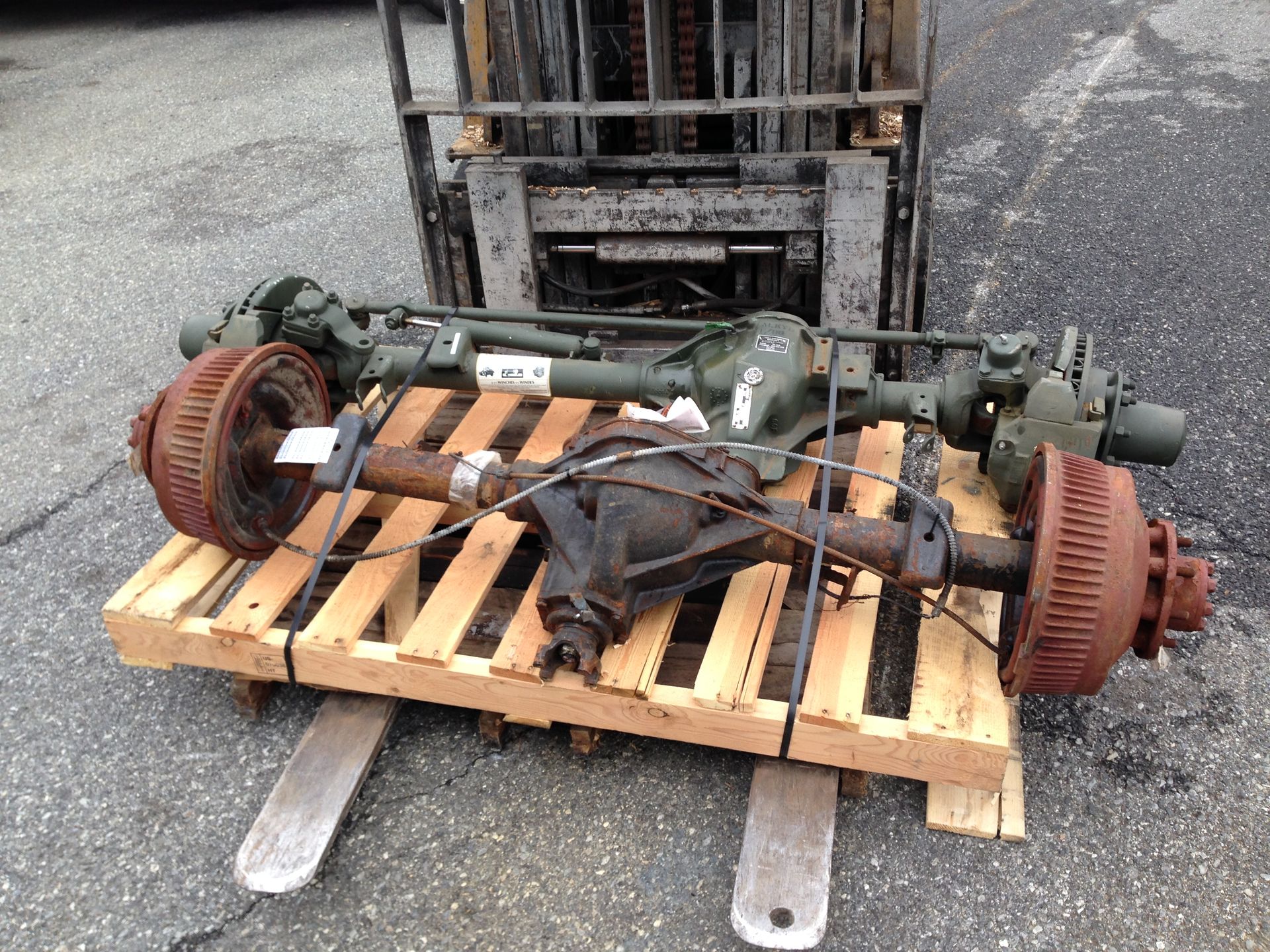

Shown below is the 14-bolt axle for the shop truck prior to disk brake conversion.

Drive Line Brake

One solution to the parking brake issue is a drive line brake that locks the driveshaft in position. This approach is particularly appealing to those who have an Atlas transfer case, since High Angle Driveline, among others, makes the following kit.

The brake can easily be installed to use the stock parking brake pedal. We had a driveline brake on the shop truck initially and found it to work okay when the truck was outfitted as a half-ton truck. Once the 1-ton driveline was installed the truck took on a significant amount of weight and the driveline brake simply would not hold the truck on even a modest incline. A non-trivial problem with the driveline parking brake is the presence of oil leaked from the powertrain. Even a slight leak can cause complete failure of the brake.

Eldorado Brakes

Another popular solution is the rear calipers from the 76-78 Cadillac Eldorado. The caliper has an integrated mechanical brake that is actuated with a cable connected to the parking brake pedal. My understanding is the brake system did not work all that well in the OEM application.

A point to consider is that the size of the caliper was engineered to work on a car, which by comparison with a fully loaded adventure rig is perhaps not enough braking power. We also tried this solution on the shop truck with poor results. The calipers were undersized for the weight of the truck and the parking brake did not hold even on modest inclines.

Electric Brakes

Many late model cars have an electric parking/emergency brake. The brake consists of a separate caliper complete with separate pads. The composition of the pads can be rather aggressive to provide as much bite as possible without a need to last through many braking cycles. The caliper contains a linear actuator that builds pressure on the pads to lock the rotor stationary.

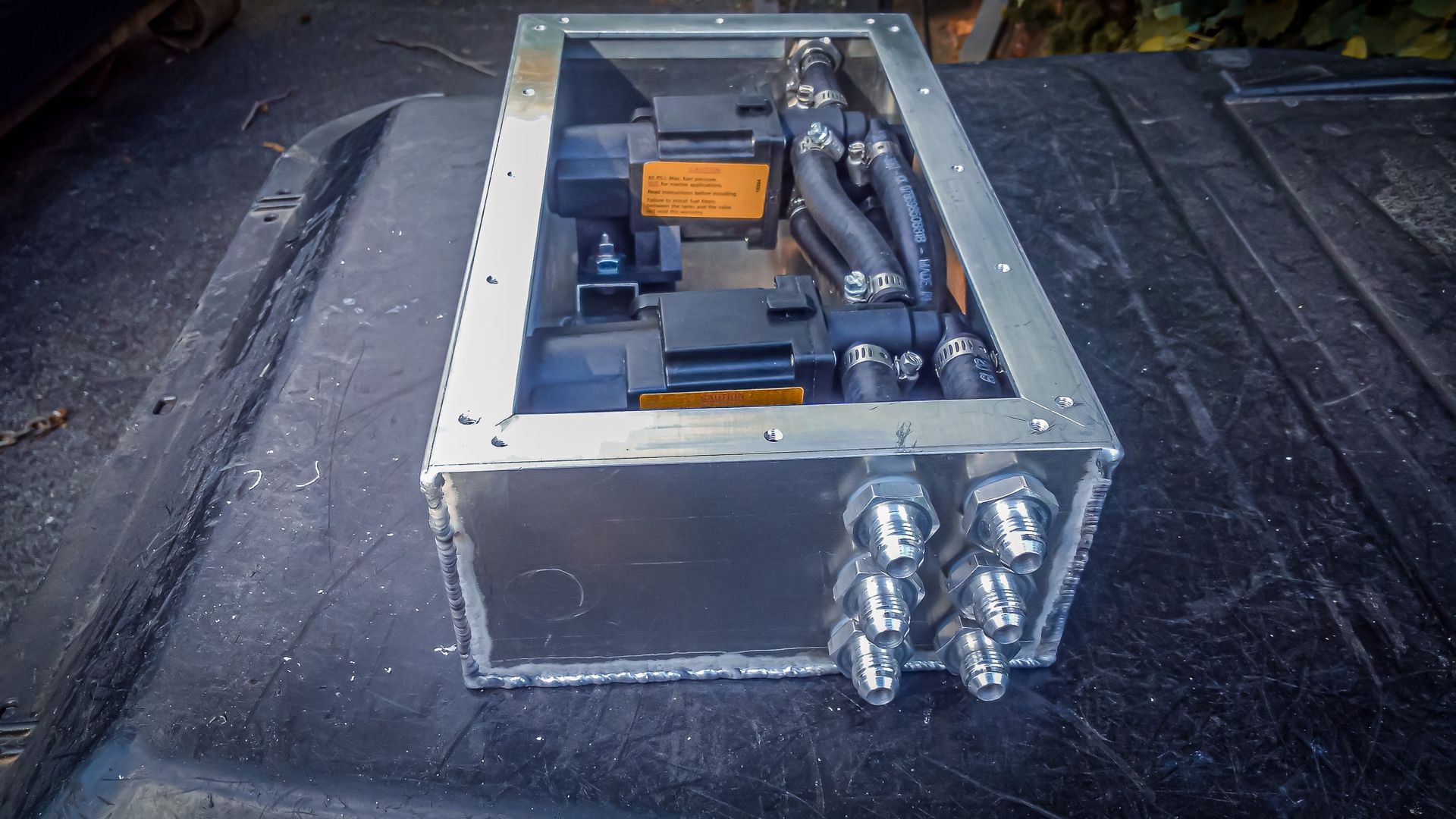

For the shop truck, we purchased an electric brake kit from Wilwood (UPC 88954509467) that includes a controller and wire harness.

Wilwood now has a high-torque version for heavy duty applications. As it turned out, the wire harness fit the shop truck perfectly without need for significant alteration. We did rework it to have a motorsports grade loom using Raychem DR-25 tubing and sealed connectors/boots we sourced from Prowire.

Another perhaps lower cost approach is to get a controller through Pantera Electronics and use Ebay Tesla electric brake calipers.

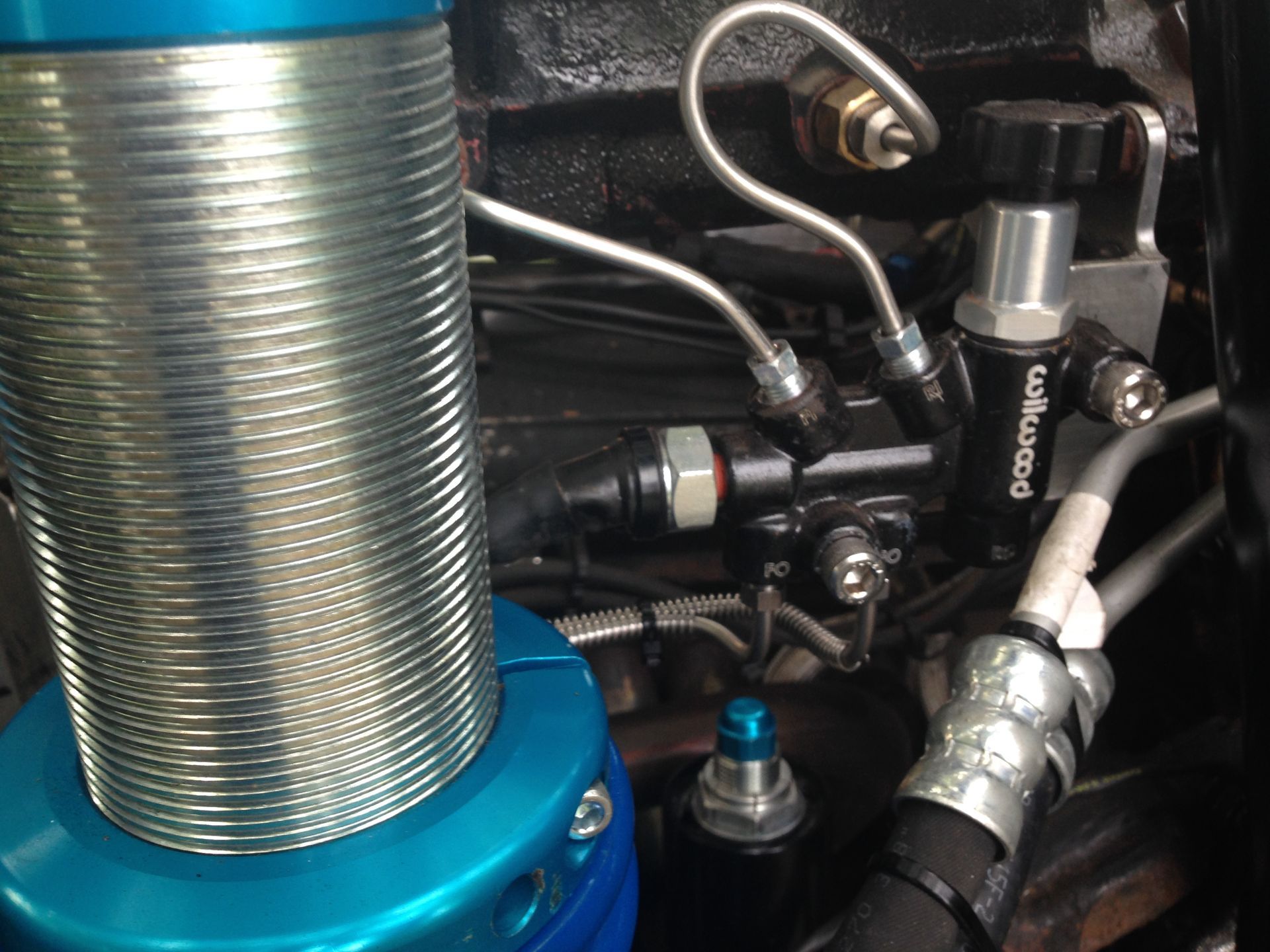

The task for our approach was to find a means of spacing the ordinary brake caliper as well as the electric caliper such that the electric caliper was properly aligned. The way we did it for the shop truck was to first mount the standard caliper using an adapter from RuffStuff. The kit from ORD would not work because it uses a spacer ring—whereas the RuffStuff bracket is bent to achieve alignment. We then worked out that we could use the Wilwood mounting plate in conjunction with a half inch aluminum adapter. All we had to do is determine the proper distance from the hub. Here is a shot of our solution.

And from the top.

While we were at it, we decided to include a Wilwood adjustable proportioning valve to tune an appropriate front/rear braking balance.

We have tested out parking brake solution for several years now and it has performed flawlessly. It will hold the truck on steep inclines and does a good job as an emergency brake. We might include our adapter plate as a product on the website in the future.